|

Side view of the Buick.

This is where the OBD connector is located. How convenient

for it to interfere with the brake pedal. Road testing with the scan

tool connected will definitely test your driving skills.

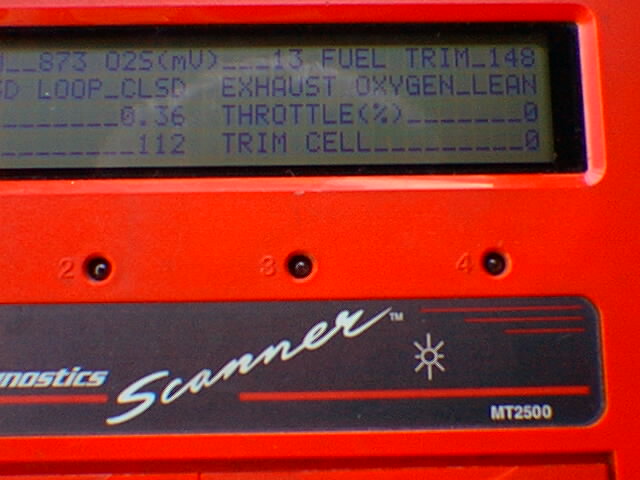

Fuel trim out of control. With fuel trim already at 148 the O2

sensor is still showing only 13 mV.

The vacuum leak was heard here at the pedal push rod boot.

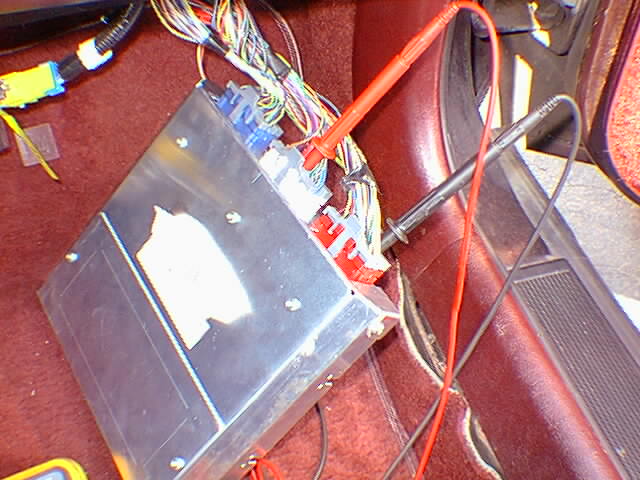

Here is a view if the Buick's ECM being back probed after

being taken down from its hiding place behind the dash.

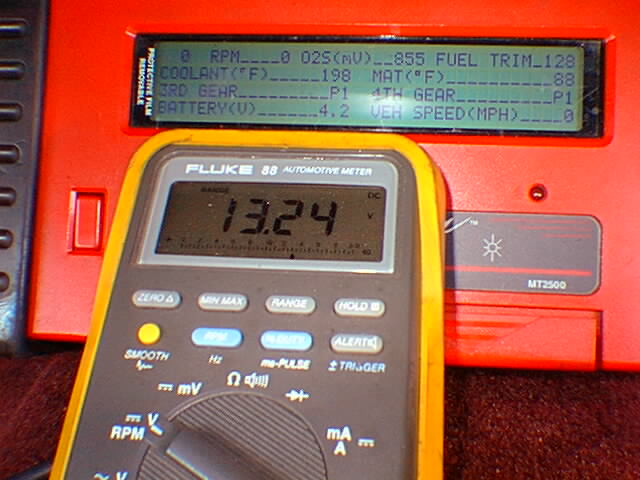

Notice the datastream is showing ECM internal voltage at 4.2

V. The volt meter clearly shows the ECM was receiving proper charging

system voltage.

|

Phantom Stall

By Mark Giammalvo, Contributing Editor

Vehicle : 1994 Buick LeSabre Custom

Powertrain: 3.8 Liter 6 cylinder 4Spd. A/T

Mileage: 117,061

Symptom: Intermittent stalling and rough running

Probably one of the worst service problems you will ever encounter is a

vehicle with an intermittent problem. Worse yet, a vehicle with an

intermittent stall condition. In fact, not many other problems will

upset a customer more than a car that intermittently stalls. Several

years back, General Motors coined the phase: "Phantom Stall" to describe

this condition. I am still amazed at the American cars today that still

have this problem. I have often wondered why the Asian and German cars

we see in the shop rarely develop intermittent stalling. It could be

just a coincidence. Then again, it might be better engineering of

critical engine management sensors and their related wiring.

It all started with one of our long time customers. A 70-year-old female

whose Buick has been stalling about every 4-5 months over the past two

years. We have driven, inspected and tested systems and subsystems on

this car during that time frame. Typically, as with intermittents, this

car will rarely become symptomatic while it is with us for service. It

has always started normally and ran well after the tow truck has dropped

it here. I must say, this customer has the patience of a saint. Some

customers get angry when we tell them we are not sure what to repair

since we cannot duplicate the problem. I have had people actually walk

out of our service department due to their refusal to understand the

complexity and time needed to diagnose some of these problems. A friend

at a Buick dealership suggested we replace the crank sensor and ignition

module. I have never been comfortable replacing parts on a shotgun

approach. In addition, it is difficult to tell a customer: "I'm going to

make some trial repairs at around 450.00, but remember, it might not

solve the problem." Then again, some would say: "I didn't build it, buy

it, or break it."

The customer had really been frightened by this recent stall event. The

vehicle had stalled out right smack in the middle of a busy

intersection. Although she was very patient and understanding, she was

getting near wit's end with this car. As usual, I was able to start the

car right off the tow truck. The customer also added that the car seemed

to run strange whenever she was descending a hill or steep grade. The

customer told me to drive it as long as needed to attempt to duplicate

the stalling. Well, lets just say I lost count after 10 lengthy test

drives. This car was running exceptionally well for a 117,000 mile car.

Finally, later in the week, the car did reveal some clues to its

ailments. Although the car never stalled for me, I was able to duplicate

the customer's complaint of trouble on steep grades. At the end of a

hilly decent, the engine seemed to be running rough. Then, at the end of

the decent, the engine would clear out and run normally. It did not seem

to be as rough as an ignition problem. To me, it felt more like a fuel

mixture change. My first thought was a mis-positioned fuel strainer or

leaking MAF intake hose. The MAF hose inspection did not reveal anything

and I did not exactly have enough test data to warrant dropping the fuel

tank. As I drove the car more, I noticed that the rough running

condition did not always relate to a hilly decent. The car seemed to be

developing a pattern of running rough during any significant braking

event. By significant braking event I mean the long brake pedal

application associated with ending a steep decent or any quick stop on

level pavement that required more than normal braking time and force.

Could the rough running be related to a brake problem? If so, that would

be a new one on me. It was time to look at scan data.

A Pattern Emerges

Although no codes were present, the scan data revealed some interesting

information. Every time I applied moderate to heavy brake pedal

pressure, the O2 sensor's value would swing lean. Now to many, this will

not come as a great surprise. Many technicians will check an idling

engine's O2 sensor's response by pumping the brake pedal quickly at a

stop. Normally, the O2 sensor will quickly swing lean as the additional

brake booster air is inhaled into the intake manifold. Then, within a

few seconds, the ECM will correct this lean condition by enriching fuel

mixture, thus resulting in an O2 sensor swing to rich. The datastream

values on this Buick were not exactly mimicking typical textbook fuel

correction values. It seemed that the longer I held down the brake

pedal, the longer the O2 sensor would report lean. At first I thought

the O2 sensor might be lazy when reporting the lean to rich transitions.

A subsequent O2 sensor test proved the sensor to be working normally.

Further analysis of the datastream revealed more to the story. As the

brake pedal was held down, not only did the O2 sensor report lean but

short term fuel trim was rising rapidly. The ECM was trying to correct

for the consistent lean report by increasing fuel injector on time. No

big surprise their, however no matter how much fuel trim the ECM added,

the O2 sensor kept reporting lean. If I held the brake pedal down long

enough, the car would start running a little rough. Although it was not

rough enough to cause a stall, this was definitely not a normal condition.

Habitable Sections Are Venting To Vacuum

Suddenly, a strange yet soft noise under the dash caught my attention.

While pushing on the brake pedal I could hear the familiar hissing sound

of a vacuum leak. When I pushed very hard on the brake pedal, the vacuum

leak could be heard louder. Although I had never seen a brake booster

cause a driveability problem, this one definitely was. If you really

forced the brake pedal down, the vacuum leak was as loud as an engine

with a large vacuum hose off. The brake booster had a tear in its

internal diaphragm. Routine ECM adaptive strategy could not compensate

for the resulting vacuum leak. As a result, the engine would run rough

due to the lean mixture at all cylinders. Another strange thing caught

my interest. Normally, if you shut off an engine while holding down the

brake pedal, the pedal will drop slightly after the engine stops. On

this car, the brake pedal would rise and even force my leg up as the

engine stopped. This incident reminded me of my sci-fi TV watching days.

I have always been amazed at the great effort in technical accuracy in

the production of the Star Trek series. Several years ago, I was

watching an episode in which the Enterprise had suffered serious

structural damage. A message on one of the computerized display screens

caught my eye. The computer screen showed the warning message:

"Environmental Systems Emergency. Habitable sections are venting to

vacuum." This statement is scientifically accurate. In that scenario,

damaged areas of the ship are "venting" into the vacuum of space. The

same was true here with the Buick. As I shut the engine off, atmospheric

pressure entered the vacuum side of the booster through the tear in the

diaphragm. This in turn moved the diaphragm and forced the brake pedal

upwards and against me.

Stalling? What Stalling?

Obviously, the Buick's story does not end their. Although the faulty

brake booster addressed the rough running condition, no one had ever

witnessed the engine stall. Even in numerous test drives after discovery

of the booster problem, the car still would not stall. However, one

morning when I started the car it began to skip violently. I was hoping

that I would now find the cause to the intermittent stalling. By the

time I reconnected the scan tool, the engine was running as smooth as a

top. After another week of test drives and extensive idling the engine

was again running poorly. A quick glance at the datastream revealed one

item out of normal parameters. The ECM internal voltage was reporting

4.2 volts instead of charging system voltage. Now, was this a problem

with the ECM grounds and feeds or a problem with the ECM itself? As

typical with this headache vehicle, by the time I got the ECM pulled

down from under the dash the problem had mysteriously corrected itself.

The next day the engine was again barely running. Scan data showed 4.1

volts to the ECM. With volt meter in hand I quickly back probed the

three separate red ECM power wires and the two black/white ECM ground

wires. The power wires all had charging system voltage and the ground

was ok at 0.02 volts. This was definitely a problem internal to the ECM.

Not that bad ECM's are uncommon in this carline but this ECM had been

given the famous "tap test," by yours truly, often over the past three

weeks. During those tests the engine never sputtered and datastream

values never changed.

Multiple Problems

In the end, the Buick had two problems. So much for me thinking

intermittents are the worst problem in servicing today's vehicles. Now

one could say that intermittent, multiple problems, are the worst

service issues in modern automobiles.

Questions:

1. A technician is trying to diagnose a vehicle that cranks but won't

run. The technician notices that the Check Engine Light won't light

during key on or during cranking. Technician A says that a faulty ECM

could be the cause of the non-illuminated check engine light. Technician

B says that a faulty ignition module could be the cause of the

non-illuminating check engine light. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

2. Technician A says that a vacuum leak could cause fuel pressure to

decrease. Technician B says that a vacuum leak could cause fuel pressure

to increase. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

3. Technician A says that a defective brake booster could cause the

brakes to inadvertently apply. Technician B says that a faulty brake

booster could the brake rotors to overheat. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

4. An exhaust leak downstream of a post catalyst O2 sensor cold cause a

change in ECM fuel trims.

True or False?

5. A MAF intake hose has a visible crack upstream of the MAF sensor.

Technician A says that the cracked hose could cause an increase in fuel

injector on time. Technician B says the cracked hose could cause a

decrease in fuel injector on time. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

6. A vehicle with a 4 speed automatic transmission will not shift into

overdrive. Technician A says a faulty overdrive switch could be the

cause. Technician B says that a faulty thermostat could be the cause.

Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

7. A customer with an OBDII software vehicle fills his tank with fuel

at a gas station. Within a mile from the station the check engine lamp

starts flashing. Technician A says that a loose fuel cap could be the

cause. Technician B says that a faulty ignition wire could be the cause.

Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

8. A vehicle pings excessively when accelerating up hills. Technician A

says that a faulty EGR valve could be the cause. Technician B says that

low fuel pressure could be the cause. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

9. Two technicians are monitoring the datastream of vehicle that is

idling in park. The technicians notice that the datastream line for the

Brake Pedal Switch is displaying the exact opposite of actual brake

pedal position. When the brake pedal is applied the datastream shows the

switch is off. When the brake pedal is released the datastream shows

the switch is on. Technician A says that the car must be in gear for

correct readings. Technician B says this could be a glitch in the scan

tool's software. Who is right?

A. Technician A

B. Technician B

C. Both Technicians

D. Neither Technician

10. Throttle body deposits can cause the ECM to decrease the engines

idle speed.

True or False?

Mark Giammalvo

Mark Giammalvo

|