Fig9 Side view of the Lebaron in front of the garage doors.

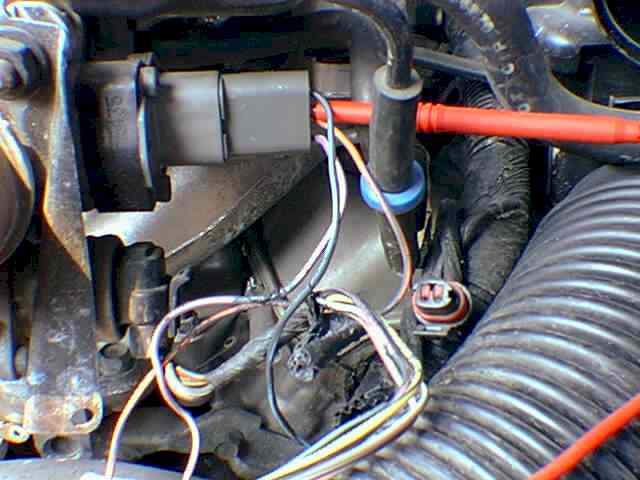

Fig3 View shows back probing the TPS signal wire (OR/DB) at the TPS

connector.

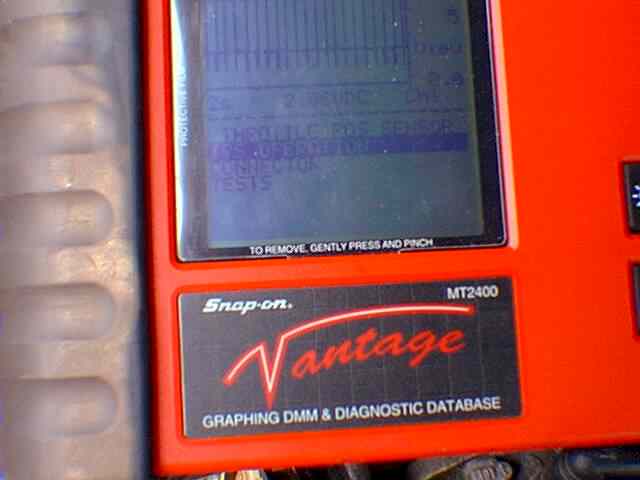

Fig7 View of datastream on the Snap-On Scanner while TPS is displaying

4.98 Volts.

Fig4 View of the Snap-On Vantage in graphing mode while back probing

the TPS signal wire (OR/DB). Notice the 60 Volt spikes.

Fig6 View of the Snap-On Vantage displaying battery voltage and 60

volt spikes on min/max while back probing the TPS signal wire.

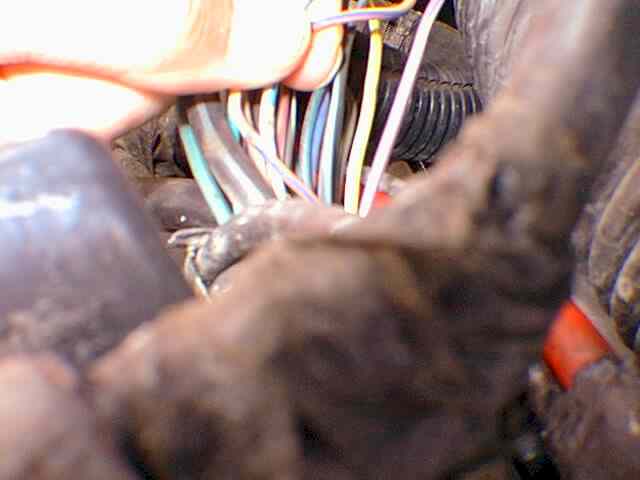

Fig5 View of Snap-On Vantage displaying injector wave form while probing

the exposed area of the Injector #1 control wire (WT/DB).

Fig. 1 View of TPS signal wire (OR/DB) and Injector #1 control wire

(WT/DB) both chafed in the same area. These wires were intermittently touching

one another in the wiring harness.

|

92 Chrysler Lebaron 2dr Convertible

3.0 Liter 4sp/AT

58,883 miles

Intermittent MIL light & intermittently runs poorly

SYMPTOMS

Recently a regular customer dropped off her 92

Lebaron ragtop with an intermittent problem. The customer reported that sometimes,

while driving, she would notice that the engine would seem to stumble and

run poorly and sometimes the MIL light would illuminate. The customer also

stated that engine temperature did not seem to matter and the problem would

come and go, and last for varying time intervals. Our initial road test

revealed a well running car with no problems. "Typical darn intermittent"

we thought.

VEHICLE OVERVIEW

Our subject vehicle is equipped with the popular drivetrain

package of 3.0 Liter, OHC engine and the Ultradrive A-604 transaxle. Engine

functions are controlled by the Powertrain Control module or PCM. An optical

ignition pickup provides two reference signals, one for cylinder ID and one

for crankshaft position, for fuel and spark delivery. A manifold absolute

pressure (MAP) sensor is used to calculate engine load instead of any type

of air flow meter. The PCM also controls the auto shutdown and fuel pump relays

to power the fuel pump, ignition coil, injectors, and oxygen sensor heater.

Besides controlling engine functions the PCM monitors and controls charging

system voltage. To aid in diagnoses the PCM also has a reset counter that

keeps track of how many ignition cycles have occurred since the last fault

code was set or battery disconnect.

Transmission functions are controlled by the Electronic Automatic

Transaxle Controller or EATX. The four speed transaxle is a fully adaptive,

electronically controlled transmission that uses feedback sensors to adjust

functions and monitor performance. With a good scan tool the EATX can supply

a wealth of diagnostic information on transaxle condition, history and current

sensor values. These computers and others are connected together by a serial

data network called the Chrysler Collision Detection System or CCD bus.

Each computer module uses this network to communicate and exchange data

with other modules in the vehicle.

THE DIAGNOSTIC

Studying the Technical Service Bulletin titles took

about ten minutes but did not reveal any similar symptoms. We called the

customer to obtain authorization for a "Level 1 Diagnostic". In short order,

a Level 1 Diagnostic at our shop is a package consisting of labor and various

tool fees, normally consisting of: 1) Visual Underhood Inspection

(VUI). 2) two hours labor. 3) Scan Tool connect and code interpretation

fee. 4) Datastream Analysis. 5) Information Access Fee (TSB & procedures

search) and, if used, 6) software fee for the Snap-On Vantage Graphing Multimeter.

After obtaining authorization we began our visual underhood inspection. A

visual inspection of all underhood equipment did not reveal anything out

of the ordinary. It was time to connect the scan tool. We found two codes

present in memory. Code 21- O2 Sensor not switching and Code 24-Throttle

Position Voltage too high. With the car running hot, the O2 sensor seemed

to switch normally from 200 to 800 millivolts. The TPS at idle was. .96V

and ok. Studying the rest of the datastream values did not reveal any abnormalities.

We decided to clear codes and road test again. Once again the car ran very

well. So well that on the test drive I wondered how much time technicians

all over the country spend test driving cars in hopes that the car will become

symptomatic.

RESULT TIME

In lieu of the fact that the car was running so well and that

no codes had returned, we decided to park the car for the day. The next

day we started the car again. This time the engine seemed to be stumbling

at first, then it would clear up and go to a higher than normal idle. Often

Chrysler vehicles will be symptomatic only for a moment when started if

there is a hard fault, because the PCM quickly supplies a substitute value

to replace the failed sensors value. A view of the datastream now revealed

some interesting information. Code 24 for high TPS was set again and the

TPS value in the data stream showed 5.00 V (fig. 7). While the car was symptomatic,

we checked the 3 TPS wires with the Vantage in the voltmeter mode. A check

of the TPS feed wire (VT/WT) revealed a normal 5.00 V reference. Testing

the TPS ground wire (BK/LB) revealed a good ground reading at 0.02 V. However,

when testing the TPS signal wire (OR/DB) we found 13.5 V (fig. 3). Now this

did not agree with the current 5 V reading on the scan tool. We believe that

the scan tool software or the vehicles computer can not display any voltage

over 5 V to the scan tool. This is probably limited since there should never

be more than 5 V on this circuit normally.

TWO THEORIES

Anyway, the voltmeter showed 13.5 V so we knew this

was the true reading. But how can 13.5 V be present on this wire? Even if

the TPS is shorted internally the maximum voltage available on this circuit

is only 5.00 V. Vantage was also capturing min/max voltage values on this

circuit. We noticed voltage was maxing at 60.00 V (fig. 6 & 4). How

could this be? We turned the engine off and left the key on. With KOEO we

noticed that the problem was gone and TPS came back to the normal .96 V.

After some pondering and discussion, we had developed two theories that

we wanted to test. Theory 1) The TPS signal wire is touching a wire that

carries battery voltage with the engine running. (Although this would not

explain the 60.00 V max readings.) Theory 2) The vehicles onboard computer

has been compromised internally in which the computer, in error, is sending

voltage out the TPS signal wire. This would have to be some internal short

or catastrophic failure since the computer should only be sampling voltage

at this pin and not supplying voltage there.

To test the first theory we decided

to let the car run again while tugging on the various underhood wiring

looms. While tugging on the main computer harness near the battery, we noticed

the TPS reading would drop to normal and the car would idle down (fig 10

& 11). More tugging created the high idle and high voltage readings

again. We were somewhat confident that the TPS signal wire was touching another

wire somewhere in the cars intestines of wiring. Now came the moment of truth.

Should we run a new TPS signal wire between the TPS and the computer and

be done with it, or should we just go a little further? Well, to quote Mitch

Schneider, "The deeper you go the more you know".

WIRING INSPECTION

Since the wiring was a fairly short run from the TPS

to the computer in the L/F fender, we decided to open the wiring loom. Beginning

at the TPS connector we pulled out the TPS signal wire (OR/DB) about twenty

inches from the connector. Not far from a junction where two wiring harnesses

meet, we found our gremlin. With the wiring loom open and the TPS signal

wire out for careful feeling and visual inspection we found a small section

of wire exposed (fig. 1, 2,8). The wire's insulation appeared to have been

crushed at one time. Only one other wire exhibited the same crushed-exposed

symptoms. That wire's color was (WT/DB). With the car running, this

wire showed the 13.5 Volts and the 60 Volt spikes. When testing this wire

with the Vantage in the waveform mode, look at what we saw (fig. 5). Look

familiar? After studying the wiring schematic we found this (WT/DB) wire

to be the Injector # 1 control wire. Since this wire was touching the TPS

signal wire, this explained the 60 volt spikes we were seeing.

After repairing both wires and taping

up the wiring harness, we cleared the TPS code and road tested the car one

final time.

As to the O2 sensor code, it never

reset and the O2 sensor activity appeared normal so we advised the customer

that there was no evidence a repair was necessary at this time for the O2

sensor. Most likely the temporary loss of fuel mixture control caused this

code to set.

One of the nice things about this

business is that it is never dull. You may see the same type of vehicle

or symptom, but that doesn't mean it will be the same old problem. Who would

of thought we would see an injector waveform riding on a TPS circuit.

Mark Giammalvo MAT, SAE

Glenn Giammalvo MAT, L1

Glenn & Mark

Glenn & Mark

|