View of the intermittent Honda.

Checking secondary ignition, (spark), with the Fluke 97 Lab Scope.

The connector inside the cabin at the right side kick panel, used

to check for on board computer fault codes.

Back probing the Manifold Absolute Pressure, (MAP), sensor signal wire

with the Fluke 97 Lab Scope.

Back probing the Oxygen, (O2), sensor with the Fluke 97.

Back probing a connected fuel injector with the Fluke 97 so we can see

the computers command signal at the injector and the injector's waveform.

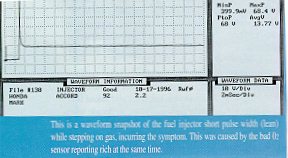

View of the waveform of a fuel injector's short pulse with, (on time),

while applying the gas pedal during the symptom window. This was caused

by the O2 sensor incorrectly reporting a rich signal to the car's computer.

As a result, the computer purposely did not spray a lot of fuel into the

engine, thus causing the hesitation.

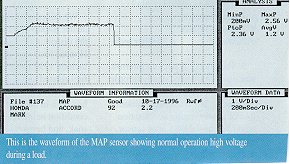

This is the waveform of the MAP sensor showing normal operation during

a load.

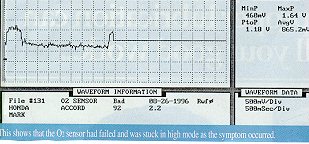

This is the waveform of the O2 sensor when it failed and was stuck

reporting to the computer that the exhaust was rich. This caused the computer

to hardly open the fuel injectors, thus causing the hesitation.

|

VEHICLE: 1992 Honda Accord

POWERTRAIN: 2.2L I4, 4-spd. A/T

MILEAGE: 41,973

SYMPTOM: Intermittent loss of power.

Those darn intermittents.

The symptom was simple enough, the customer reported that when driving,

the car would momentarily loose power, whether the accelerator was depressed

or held steady made no difference. The problem was that it was very intermittent.

Oh yes, those darn intermittents, not exactly every technicians

favorite type of diagnostic problem. They bring back memories of intermittent

problems that cost endless hours of diagnostic time only to find a loose

fuse connection as the cause of it all. Any customer complaint we receive

about any intermittent problem is usually followed by a long explanation

to the customer of how complicated some systems can be. A typical powertrain

control module monitors at least a dozen sensors, through more wires than

a small home, to control fuel and spark delivery as well as other sub-systems.

The point we stress the most to customers, is that we most likely will need

to be able to duplicate the problem in order to diagnose its cause.

System specifics

The Honda in question is typical of the modern offerings from the

orient, but a few not so typical features are worth mentioning. The PGM-FI,

(Programmed Fuel Injection) control unit does not measure intake air with

any kind of sensor, instead injector duration is based on a preprogrammed

duration that is derived from RPM signal and MAP sensor signal, and

then modified by other sensors. The Engine Control Module will protect the

engine from over revving by cutting off fuel at any RPM reading above 6300.

The Engine Control Module also controls charging system voltage in accordance

with charging system load so fuel economy can be increased during times of

light electrical load.

Were do we begin

Two or three road tests later we had some useful information to

start with. The symptom, although very intermittent, could always be duplicated

the same way. When the car was driven, allowed to hot soak for a short time,

and then driven for a few minutes, the Honda would always suffer a loss

of power that would only last a few seconds, and the customer was correct

in reporting that accelerating made no improvement.

We started by checking for factory service bulletins,

it is the best first diagnostic effort if you have access to the information,

but in this case none were listed that matched our Honda's symptoms. Next

we checked for trouble codes stored in memory. Jumpering the two wire connector

located under the passengers side of the dash, is all it takes to make the

dash check engine warning lamp flash out codes. No codes were present, but

that is what we expected because the problem was so intermittent and never

had illuminated the check engine lamp.

With in shop diagnostics used up, no we do not

have a dyno, we decided it was time to hit the road. First we tried to duplicate

the condition with our lab scope monitoring a fuel injector waveform. After

a few more tries we finally got it to act up and found the pulse width, or

injector on time , was being decreased as the Honda lost power. This explains

the power loss, but now we realized we would need to find the input signal

that led to this decreased fuel supply moment. With one power loss event

sometimes taking hours to duplicate we searched for an easier solution.

We talked to the local Honda dealer for advise, and they reported

the distributor recall on the 1991 Hondas had been changed to now include

1992 models. This cars symptoms do not match any of the failed Honda distributors

we had seen in the past, but with the condition being related to a hot soak,

and being so hard to duplicate, it seemed worth a try. Well one day later

our Honda was back with its brand new distributor, compliments of Honda,

but as the drivers brought the keys back to the service desk, they reported

the intermittent power loss was still present.

Back on the road with the lab scope, we decided to monitor the MAP,

or manifold absolute pressure sensors output next. Any false indication

of reduced load could cause the lessened injector pulse width our Honda

was plagued with. Hondas MAP sensor is a silicon diaphragm strain gauge style

that directly varies voltage output in relation to manifold pressure. When

the symptom occurred MAP voltage gave no indication of a load change, meaning

the MAP sensor signal was not our problem, and that we had just wasted a

few more hours of diagnostic time driving the Honda.

In another effort to save time we put in a call

to one of our favorite diagnostic hot lines and asked for their advise.

Trying to decide when to call a hotline for help can be a problem itself.

If you call to early in the diagnosis they will tell you to check the basic

and easy to verify things first, but you probably already knew to do that.

If you call them to late you can find out you have been wasting time because

the problem is common enough that they have seen it before. We were calling

just a little late. They suggested we rode test and monitor the oxygen sensor,

that on this vehicle , the oxygen sensor was the primary fuel control when

ever the vehicle is above idle speed. Maybe we should of have known that

already, but we work on more domestic car problems and they typically do

not rely so strongly on oxygen sensor input.

Wait a minute, lets place the blame were it

belongs. Should car companies supply us with more information when it comes

to operation logic? This is one of our biggest pet peeves, and about once

a week at our shop a job will come in, and we will notice that if more information

were available the diagnosis would have taken less time. I realize car companies

want to keep operation strategies secret but we are not looking for a lot

of numbers or specifics. Just give us some simple guidelines like which sensor

has what priority and when. Like what sensor signal amount would be drastic

enough to over ride another sensor. Many technician taking the ASE advanced

level L1 test report how difficult the test is, yet more information is

given about the generic vehicle used in the test than some major car companies

actually supply for there own cars. Hopefully the L1 test will give some

auto manufactures a clue as to how much information a good technician will

need to repair their vehicles.

On the road again

Driving the Honda again, this time monitoring the oxygen sensor

circuit, we found the sensor signal looked good while the car was not acting

up. The sensor moved rapidly between a low voltage reading, lean indication,

to a high voltage reading, rich indication, just as it should. But when

the symptom appeared again the oxygen sensor stopped swinging lean to rich,

and just held a steady high voltage signal for a good three seconds. This

false rich indication tricked the Electronic Control Unit into reducing fuel

injection delivery and resulted in our power loss symptom. Intermittent oxygen

sensors problems are not very common, but this Honda proved anything is possible.

This particular oxygen sensor also has a heater element that could explain

how the sensor failed with a fixed higher than normal voltage reading. Somehow

the hot soak and short test drive would make the sensor fail allowing

voltage from the heater circuit to bleed into the sensor side of the circuit.

With the new oxygen sensor installed we repeated

our road test routine and kept monitoring the oxygen sensor circuit. The

symptom and hung up oxygen sensor reading never resurfaced after five road

tests verifying the repair was complete. Three days after the car first

rolled in the shop, the problem was finally solved with a simple oxygen

sensor replacement. Those darn intermittents.

Mark Giammalvo MAT, SAE, L1

Glenn Giammalvo MAT, L1

Glenn & Mark

Glenn & Mark

|