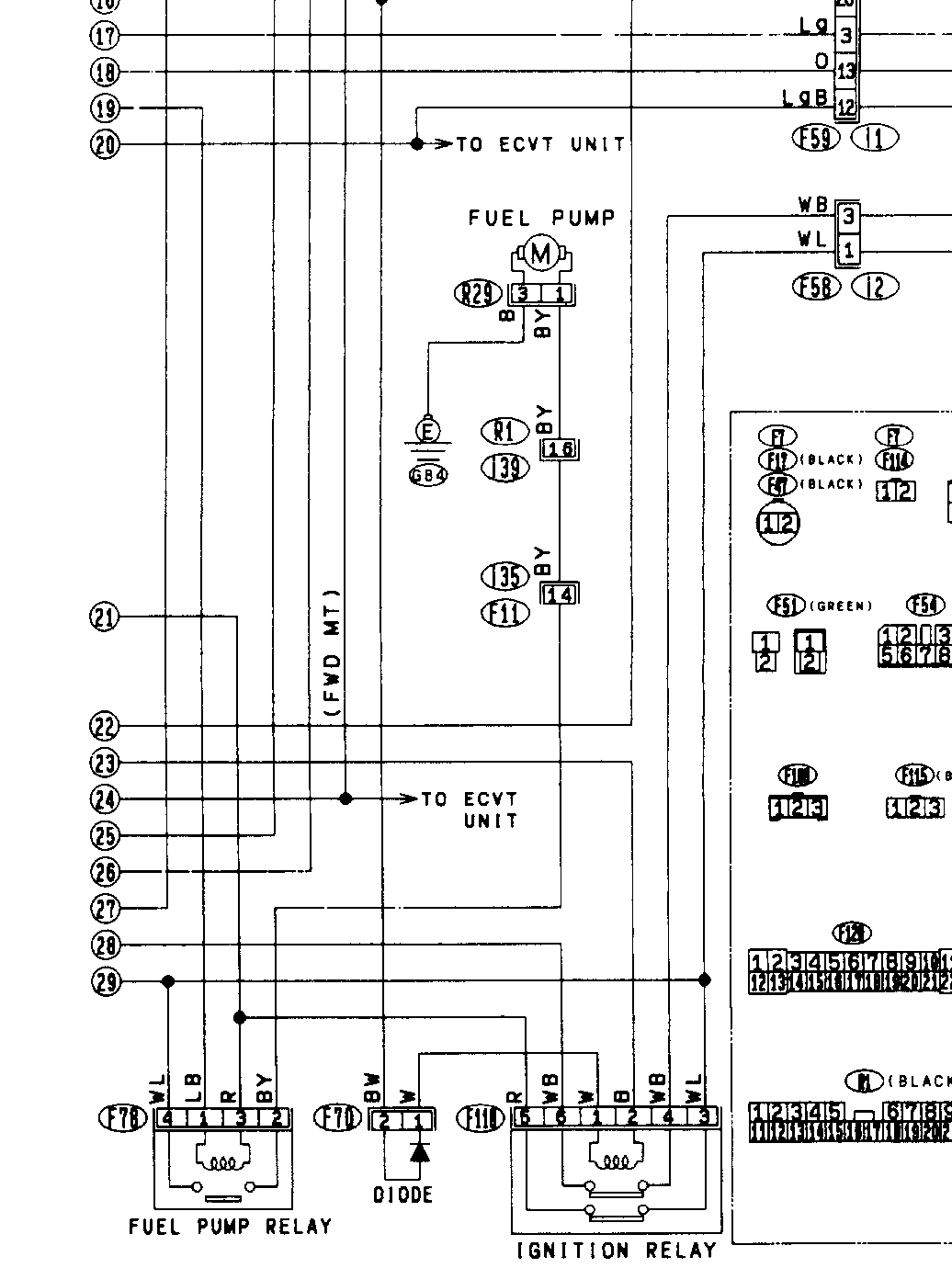

Here is the partial wiring diagram of the Subaru's Ignition and Computer

Power Circut.

|

"It doesn't do it all the time"! Do you still cringe when a customer

says that? I know I still do. For many of us intermittent problems are bittersweet.

It's a love hate relationship. In one way you hate the large amount of time

you must spend testing or even test driving the vehicle. On the other hand,

once you have figured out the problem, the solution can bring an overwhelming

sense of satisfaction. It is that sense of satisfaction that most of us technicians

live for.

Qualify the vehicle.

In our industry an "intermittent" is generally a problem that occurs

at least once per day. That being said, you need to begin to qualify your

customer. "Just how intermittent is it"? This should be one of your initial

questions to a customer who requests service for an intermittent problem.

I warn you now: If the customer describes a vehicle that is symptomatic

only once or twice a week, don't bother wasting your time. A car like this

actually has what many like to call a "random problem" an not an intermittent.

If you dare to diagnose a random problem you will most likely spend a lot

of "unbillable" time test driving the car just to see if the problem rears

its ugly head. In a polite way advise your customer that their vehicle has

to be symptomatic at least once a day in order to efficiently and economically

diagnose. This can be difficult for a customer to comprehend. We have developed

a hand out at our shop to help explain this to customers. You may wish to

do the same.

Qualified!

Once you actually have a legitimate intermittent problem, ask the

customer as many questions as you can about the nature of the problem. The

answers to these questions will start your mind painting a picture of the

problem and in the wink of an eye your mind will already be busy at plotting

a solution.

Most intermittent problems fall into one of two categories. The first

is a vehicle that will not start intermittently. If this is the case try

to question the customer to determine if the engine is actually turning over

when the problem occurs. This way you will know weather or not you can eliminate

the starting circuit of the car. I'd like to have a dollar for every repair

order in the country that has been written up as: "Customer reports car would

not start" when actually a little more questioning would have led to the

complaint being: "Customer reports car cranked over but would not run". Two

entirely different problems that, more often than not, do not get explained

correctly at customer write up.

The second type of problem is the intermittent running problem. These

are by far the most interesting to diagnose. They can also be the ones that

send you home at night with an upset stomach. The intermittent running problem

can manifest itself in many different forms like: Hesitations, stalling, bucking,

pinging, racing, etc. Question the customer further to find out important

details that will effect diagnosis like: Does the problem occur more when

the engine is hot or cold, after a hot soak, during inclement weather, when

a certain accessory is turned on or off, during acceleration or deceleration,

during turns, uphill or downhill?

Once you have noted the answers to these questions advise the customer

of the initial tests you will perform and the cost of those tests. Make

sure the customer is very clear in understanding that your initial tests

may not find the problem but will most likely point you to a certain system

on the vehicle that needs specific testing. We ask our customers to authorize

a "Level One Diagnostic, (LID)" Our LID is a package that includes a visible,

(no tools), underhood inspection for obvious problems, scan-tool connect

fee, and one hours labor to cover the technicians time reading the datastream,

road testing, etc. After your initial tests are complete you can now

begin to formulate a differential diagnosis. In a differential diagnosis

you are basically taking your test results and the vehicles symptoms and

listing all the possible causes. At this point you may have actually discovered

the cause of the problem. If so, you can advise the customer as to the cost

of repair. Generally the vehicle still requires further testing to pinpoint.

If so, you can now contact your customer to ask if they will authorize additional

testing time and/or other specialized tool costs to aid in further diagnosis.

If the diagnosis has gone on longer than you like, a call to a tec-line may

be helpful. If the customer does give you authorization to continue, be sure

to give them status and current cost updates after each actual billable hour

you spend on their car. That way there will be no question as to the amount

owed should the customer decide at some point to halt the testing.

Digging In.

In this example we will demonstrate the intermittent starting problem.

Specifically a "cranks but won't run problem". By far the most interesting

yet difficult problems will be those with the smallest symptom window. The

symptom window is the actual time frame in which the vehicle is symptomatic.

In some of the more difficult cases the symptom window can be as short as

1-2 minutes long. This means any testing you hope to accomplish must be done

during that small time frame. In the worst cases the symptom window is short

and the time between symptom windows is long. An example of this would be

a vehicle that has a problem for only 1 minute and the problem only occurs

once per day. Lets take a 1994 Subaru Justy 3 cylinder that we repaired as

an example. This customer reported that each morning after being parked all

night, the vehicle would crank but would not start. The customer went on to

say that if the vehicle were cranked a second or third time the car would

start and be fine for the rest of the day. We had to keep this vehicle for

a total of six days because the symptom window was so short and the time between

windows was so long. What made matters worse was the fact that on three of

the days the car started fine with no problem. Nothing to test on those three

days! To make a long story short, we were able to compile some interesting

test data from several of the mornings when the car would not start for that

first minute. When a car has a starting problem like this we generally install

a spark tester on one of the plug wires and we disconnect one of the fuel

injectors and plug in a noid light. Generally speaking, if the car will neither

spark nor run the noid light we start leaning towards a crank sensor system

problem. Hence you begin your differential diagnosis. (Don't forget that

some cars with a snapped timing belt will show up as no spark and no illuminated

noid light). We found that while cranking their was no spark and no flashing

noid light. So now your thinking...timing belt or crank sensor right? Well,

not exactly. The solution became a lot closer when I was sitting in the vehicle

staring at the dash with the key on one morning after the car would not start.

While sitting their I heard a relay "ping" and at that moment I noticed the

check engine lamp popped on and I heard the fuel pump run its two second

prime. The lamp should have been on as soon as the key was turned on for

the bulb test but it came on about one minute after the key had been on.

Referring to Figs. 1 and 2 we could see in the schematic that the power for

the ECM, check engine light, coil, igniter, and the fuel pump came

from what Subaru calls the "ignition relay". The relay is a "dual contact

relay" in which one contact sends power to the coil and the igniter while

the other contact sends power to the ECM, check engine light and fuel pump

relay. We decided to hook up a volt meter to monitor the that relay. When

the car would not start the next morning our volt meter showed that the one

of the contacts in the relay, (wire WB), was fine as the ignition coil had

its 12 volt supply. The other contact in the relay, (wire R) did not have

power. This side of the relay supplies power to the ECM and the fuel pump

relay. A simple tap on the relay and the power was their. A new relay

resolved the problem. Most of us don't think to bother looking at the check

engine light on a car that "cranks and won't run" but I have forced myself

to make it a habit. We recently had a late model Ford Explorer where the

customer had an intermittent "cranks won't run" complaint. Upon initial inspection

of the vehicle, one of the first things I noticed was that the check engine

light was not on at key on. A simple tap on the PCM relay in the underhood

relay center put the check engine light on and the fuel pump was heard making

its two second prime. I guess now I could say I solved this with a little

luck and past experience. Another faulty relay.

Then their are the cars with the intermittent running problems. These

cars run well most of the time but act strange intermittently. First, try

to duplicate the problem based on the answers the customer gave to the questions.

If the problem was a bucking in inclement weather then you might road test

the car after wetting down the secondary ignition components. Sometimes when

a customer reports the symptom of bucking, the first thing we think of is

ignition. If the vehicle is a late model Ford the torque converter may be

suspect as this has been shown to be a weakness in some of their models. Once

you duplicate the condition you will develop a hunch or "gut feeling" as

to weather the problem seems like a lack of fuel, ignition problem, etc. At

this point you may want to check the service bulletins on the vehicle for

the system you think is suspect. If no relevant bulletins are found

you must push on with further testing. Not to pick on Subaru again but we

recently had a 1996 Subaru Legacy 4 cylinder that developed a very nasty intermittent

hesitation. Fortunately this car exhibited several symptom windows per day

in which to analyze the problem. In fact, parking the car for about a half

hour or more and restarting it almost always forced the problem to surface.

The difficult part was that the symptom window was short. When the vehicle

hesitated it did so for all of 1-2 minutes then the hesitation was gone until

the car was parked a half hour and driven again. This car has an OBDII datastream

but the data updates on the scanner were so slow that I did not believe the

scanner would have caught the problem. Beware that this is becoming an increasing

problem on OBDII cars with generic scan tools. (The government said we as

independents had to communicate easily with the car but did anyone say at

what speed?) Of course the sensitive OBDII computer did not store any fault

codes! Anyway, a recorded movie of the datastream looked good during the

hesitation so we decided to connect the Snap-On Vantage to the TPS signal

wire. When the vehicle hesitated the TPS showed a normal voltage reading

that increased with throttle angle. Eventually we monitored fuel injector

pulse width and the MAF signal wire. When the car hesitated and I was applying

throttle, the fuel injector pulse width did not get any greater. That would

indicate that someone was lying to the ECM telling it that more fuel was

not needed, but who? The MAF sensor showed no more air entering the engine.

That must be the problem right? Cleaning the sensor's sampling wire

and even substituting another MAF sensor did not solve the problem. The sensor

still showed a decrease in air entering the engine. What was actually happening

was that the MAF sensor was correctly showing a decrease in air entering

the engine since the engine hesitated for another reason. What I thought

was a cause was actually an effect. Be careful not to get fooled with strategy

scenarios like this. It's like saying: "What came first the chicken or the

egg"? Its no different than monitoring a crank sensor signal and noticing

the frequency change when the engine slows down. You have to ask yourself:

Did the signal I just saw on my scope change due to a problem with the sensor

and that caused the engine to slow down? Or did the engine slow down for

another reason and the crank sensor is just reporting the change? Makes you

think harder doesn't it? In the end the problem with this vehicle was the

O2 sensor. In Fig. 3 the Snap-On Vantage is shown in dual graph mode. The

top graph is the O2 sensor signal wire to the ECM. The bottom wire is the

O2 sensor heater voltage. Normally .2 to .8 volts is observed on the O2 sensor

signal wire as the O2 sensor switches back and fourth from lean to rich.

What actually happened here is that some of the O2 heater voltage bleed across

inside the O2 sensor to the signal wire. As you start out on the test

drive at first their was no hesitation. This is due to the fact that the

car is still in open loop. As you can see in Fig.4, the hesitation occurs

the moment the car goes into closed loop. During closed loop the O2 sensor

signal is believed by the ECM. At that point the voltage is still way too

high. The ECM believes this reading and views it as a rich exhaust. Therefore,

fuel delivery is reduced and the hesitation occurs. After about 30 seconds

the voltage comes back down into normal range and the car is fine for the

rest of that trip. Once the car is parked for about ½ hour the cycle

repeats itself and the hesitation is back again.

Their is no doubt that intermittent problems are getting more frequent

as vehicles are built with more electronics. Hopefully you can apply the

ideas presented here to some of those future problems.

Mark Giammalvo MAT, SAE, L1

Mark Giammalvo MAT, SAE, L1

|